Cheap price Open Type Laser Cutting Machine - Taiwan quality Chinese price MVP866 Machine center – BiGa

Cheap price Open Type Laser Cutting Machine - Taiwan quality Chinese price MVP866 Machine center – BiGa Detail:

Processing size

| Model | Unit | MVP 866 |

| Work table | ||

| Table size | mm(inch) | 950×600(38×24) |

| T—solts size( solt number x widthx distance) | mm(inch) | 5×18×110(0.2×0.7×4.4) |

| Maximum load | Kg(lbs) | 600(1322.8) |

| Travel | ||

| X-axis travel | mm(inch) | 800(32) |

| Y—axis travel | mm(inch) | 600(24) |

| Z—axis travel | mm(inch) | 600(25) |

| Distance from Spindle nose to table | mm(inch) | 120-720(4.8-28.8) |

| Distance from spindle center to column surface | mm(inch) | 665(26.6) |

| Spindle | ||

| Spindle taper | type | BT40 |

| Spindle Speeds | r.p.m | 10000/12000/15000 |

| Drive | type | Belt-tvpe/Directly coupled/Directlv coupled |

| Feed rate | ||

| Cutting feed rate | m/min(inch/min) | 10(393.7) |

| Rapid on (X/Y/Z) axes | m/min(inch/min) | 36/36/30(48/48/36) |

| (X/Y/Z) fast moving speed | m/min(inch/min) | 1417.3/1417.3/1181.1 (1889.8/1889.8/1417.3) |

| Automatic tool changing system | ||

| Tool Type | type | BT40 |

| Tool capacity | set | Arm 24T |

| Maximum tool diameter | m(inch) | 80(3.1) |

| Maximum tool length | m(inch) | 300(11.8) |

| Maximum tool weight | kg(lbs) | 7(15.4) |

| Tool to tool change | sec | 3 |

| Motor | ||

| Spindle drive motor Contimious operation / 30 min rated |

(kw/hp) | MITSUBISH 5.5/7.5 (7.4/10.1) |

| Servo drive motor X, Y, Z axis | (kw/hp) | 2.0/2.0/3.0 (2.7/2.7/4) |

| Machine floor space and weight | ||

| Floor space | mm(inch) | 3400×2500×3000 (106.3×98.4×118.1) |

| Weight | kg(lbs) | 7000(15432.4) |

Machine Center

High-speed high-precision vertical machining center adopts imported control systems such as Mitsubishi and Fanuc and its supporting servo drives and motors to realize three-axis or multi-axis linkage. It is suitable for complex structures, multiple processes, high precision requirements, and multiple installation Only clamping and adjustment can complete the processing of the processed parts. The machining center can process cabinets, complex curved surfaces, shaped parts, plates, sleeves, and plate parts, and is widely used in aerospace, automotive locomotives, instrumentation, light industrial textiles, electronic appliances, and machinery manufacturing.

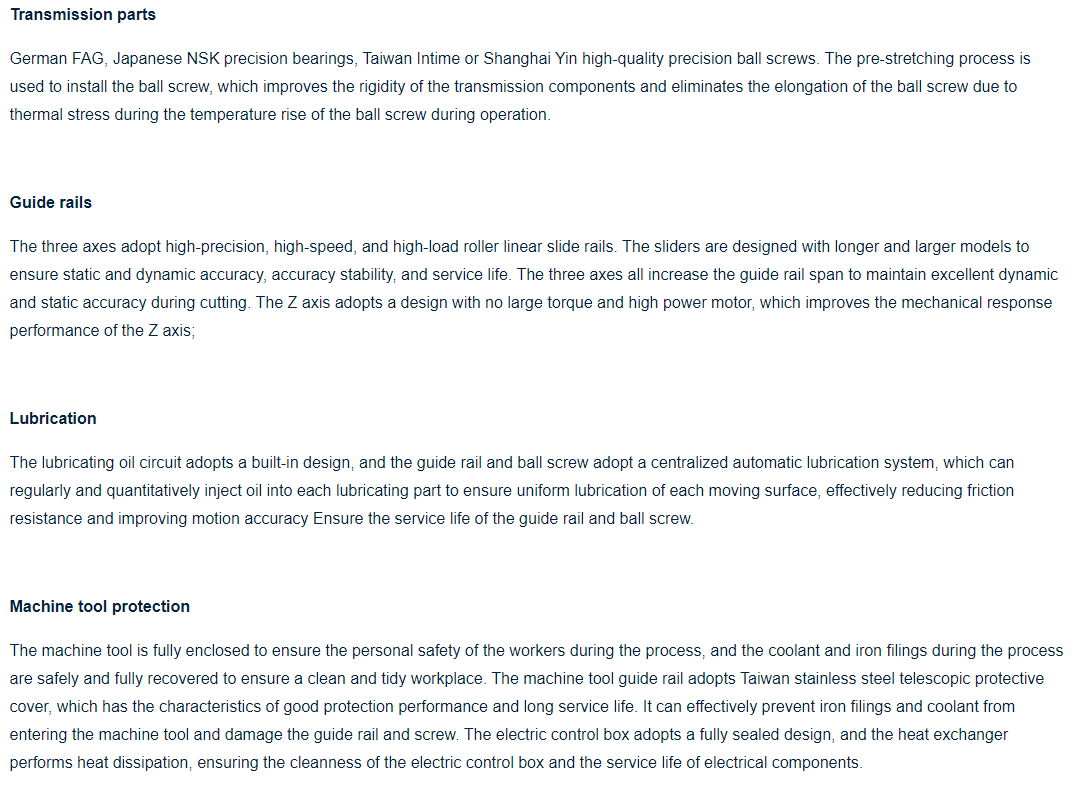

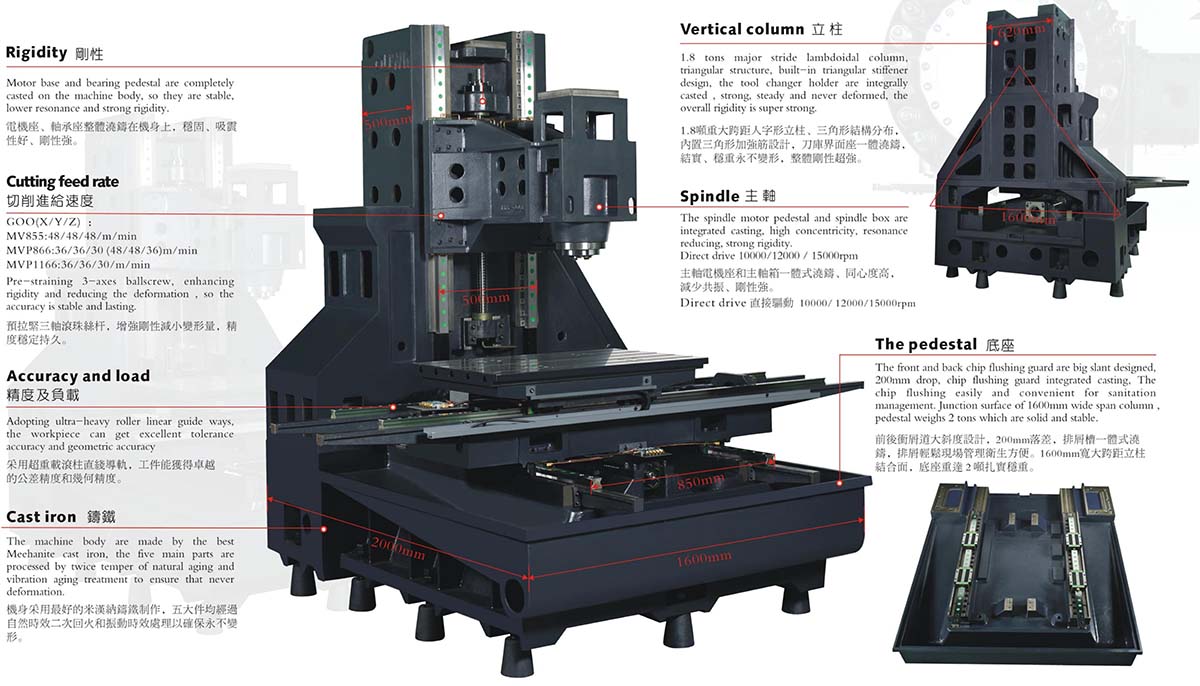

Whole machine structure

The body parts are made of high-quality FC300 brand cast iron, the internal reinforcement is strengthened, all undergo natural aging, secondary tempering and vibration aging treatment, and the finite element analysis is carried out through special design software. It has high strength, good stability and is not easy Deformation and other characteristics. The large-width base design makes the overall force of the machine tool more uniform and the operation more stable. The large-angled herringbone column structure adopts high-density, high-strength rice-shaped ball mesh cross reinforcing ribs to effectively prevent the deformation and vibration of the column. The screw support bearing seat adopts the integral casting design with the casting body, and the workbench screw nut seat and the worktable are integrated casting design, which greatly improves the rigidity and stability of the machine tool during movement. Reasonable structure, rigorous design and fine craftsmanship effectively ensure the rigidity of the whole machine and the accuracy and stability of long-term use.

Main shaft

box-type short nose end spindle head structure, internal rib reinforcement, main shaft motor mounting seat and box body adopt an integrated structure design, strong rigidity, good shock absorption, effectively reducing the vibration and resonance of the main shaft during operation. Equipped with Taiwan famous brand spindle, the spindle adopts imported super-precision bevel ball bearing and large-span support design, so that the spindle can withstand strong radial and axial thrust and eliminate the vibration caused by heavy load cutting. The maximum speed of the main shaft is 15000RPM, coupled with the transmission of the gapless precision coupling, which has the characteristics of high precision, low noise, low power loss and fast response. The spindle motor servo adopts the power supply to rise, which greatly improves the response speed of the motor when it starts. The nose of the spindle adopts multi-maze and air curtain dustproof design, which can effectively prevent the entry of debris and ensure the accuracy and life of the spindle for long-term use.

Product detail pictures:

Related Product Guide:

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for Cheap price Open Type Laser Cutting Machine - Taiwan quality Chinese price MVP866 Machine center – BiGa , The product will supply to all over the world, such as: Hamburg, Croatia, Bulgaria, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.