CNC Mirror Spark Machine

Parameter table

Capability parameter table

| Item | Unit | Value |

| Table Size (Long × Wide) | mm | 700×400 |

| Internal Dimension of Processing Liquid Tank (Long × Wide × High) | mm | 1150×660×435 |

| Liquid Level Adjustment Range | mm | 110–300 |

| Maximum Capacity of Processing Liquid Tank | l | 235 |

| X, Y, Z Axis Travel | mm | 450×350×300 |

| Maximum Electrode Weight | kg | 50 |

| Maximum Workpiece Size | mm | 900×600×300 |

| Maximum Workpiece Weight | kg | 400 |

| Minimum to Maximum Distance from Working Table to Electrode Head | mm | 330–600 |

| Positioning Accuracy (JIS Standard) | μm | 5 μm/100mm |

| Repeated Positioning Accuracy (JIS Standard) | μm | 2 μm |

| Overall Dimension of Machine Tool (Length × Width × Height) | mm | 1400×1600×2340 |

| Machine Weight Approx. (Length × Width × Height) | kg | 2350 |

| Outline Dimension (Length × Width × Height) | mm | 1560×1450×2300 |

| Reservoir Volume | l | 600 |

| Filtering Method of Machining Fluid | A | Exchangeable Paper Core Filter |

| Maximum Machining Current | kW | 50 |

| Total Input Power | kW | 9 |

| Input Voltage | V | 380V |

| Optimum Surface Roughness (Ra) | μm | 0.1 μm |

| Minimum Electrode Loss | - | 0.10% |

| Standard Process | Copper / steel, micro copper / steel, graphite / steel, steel tungsten / steel, micro copper tungsten / steel, steel / steel, copper tungsten / hard alloy, copper / aluminum, graphite / heat resistant alloy, graphite / titanium, copper / copper | |

| Interpolation Method | Straight line, arc, spiral, bamboo gun | |

| Various Compensations | Step error compensation and gap compensation are performed for each axis | |

| Maximum Number of Control Axes | Three-axis three-linkage (standard), four-axis four-linkage (optional) | |

| Various Resolutions | μm | 0.41 |

| Minimum Drive Unit | - | Touch screen, U disk |

| Input Method | - | RS-232 |

| Display Mode | - | 15″ LCD (TET*LCD) |

| Manual Control Box | - | Standard inching (multi-level switching), auxiliary A0~A3 |

| Position Command Mode | - | Both absolute and incremental |

Sample Introduction

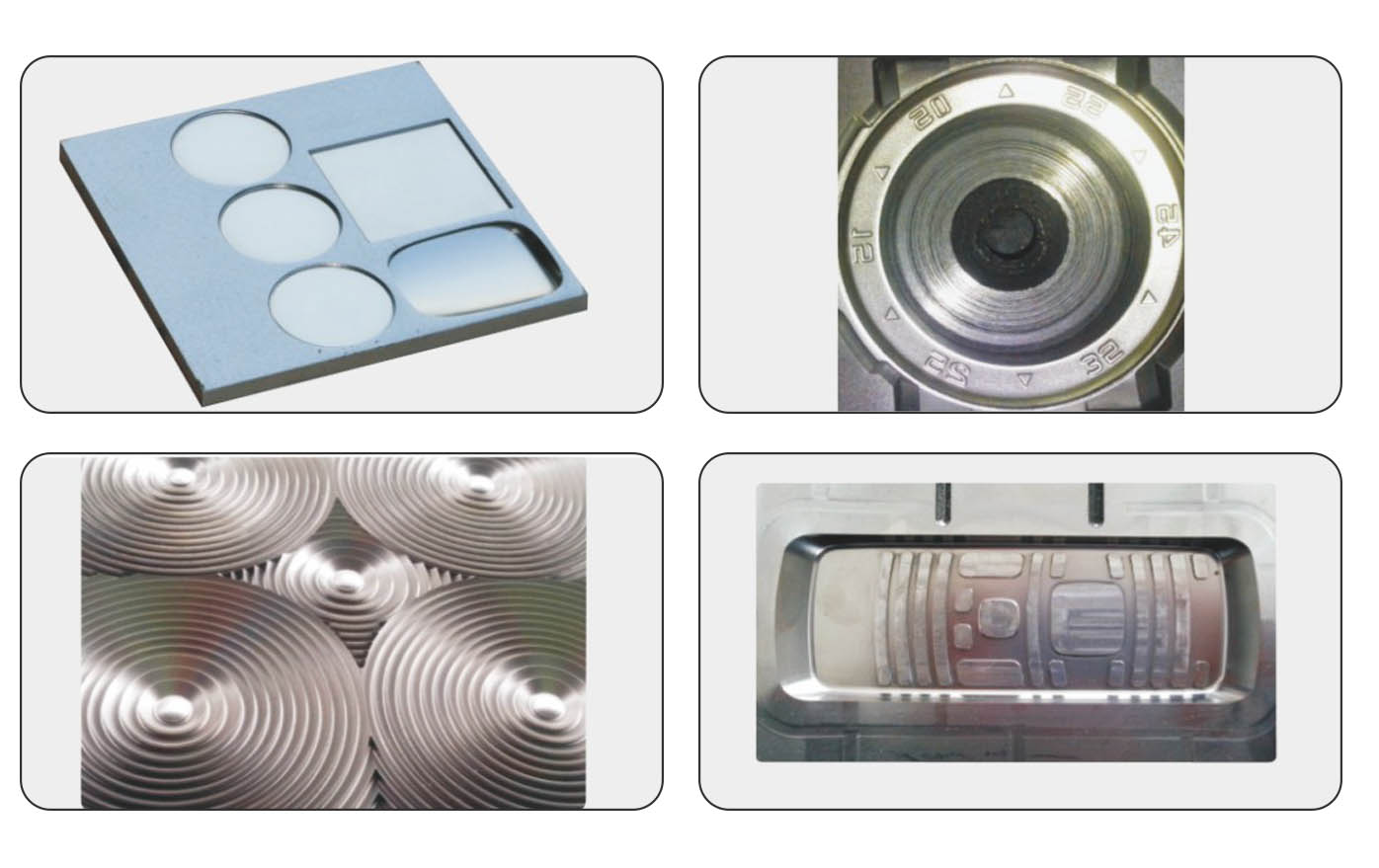

Comprehensive Processing Examples (Mirror Finish)

| Example | Machine Model | Material | Size | Surface Roughness | Processing Characteristics | Processing Time |

| Mirror Finish | A45 | Copper – S136 (Imported) | 30 x 40 mm (Curved Sample) | Ra ≤ 0.4 μm | High Hardness, High Gloss | 5 hours 30 minutes (Curved Sample) |

Watch Case Mold

| Example | Machine Model | Material | Size | Surface Roughness | Processing Characteristics | Processing Time |

| Watch Case Mold | A45 | Copper – S136 Hardened | 40 x 40 mm | Ra ≤ 1.6 μm | Uniform Texture | 4 hours |

Razor Blade Mold

| Example | Machine Model | Material | Size | Surface Roughness | Processing Characteristics | Processing Time |

| Razor Blade Mold | A45 | Copper – NAK80 | 50 x 50 mm | Ra ≤ 0.4 μm | High Hardness, Uniform Texture | 7 hours |

Telephone Case Mold (Mixed Powder Processing)

| Example | Machine Model | Material | Size | Surface Roughness | Processing Characteristics | Processing Time |

| Telephone Case Mold | A45 | Copper – NAK80 | 130 x 60 mm | Ra ≤ 0.6 μm | High Hardness, Uniform Texture | 8 hours |

Write your message here and send it to us