Low price for Vertical Machine Center Cnc - Taiwan quality Chinese price MVP1166 Machine center – BiGa

Low price for Vertical Machine Center Cnc - Taiwan quality Chinese price MVP1166 Machine center – BiGa Detail:

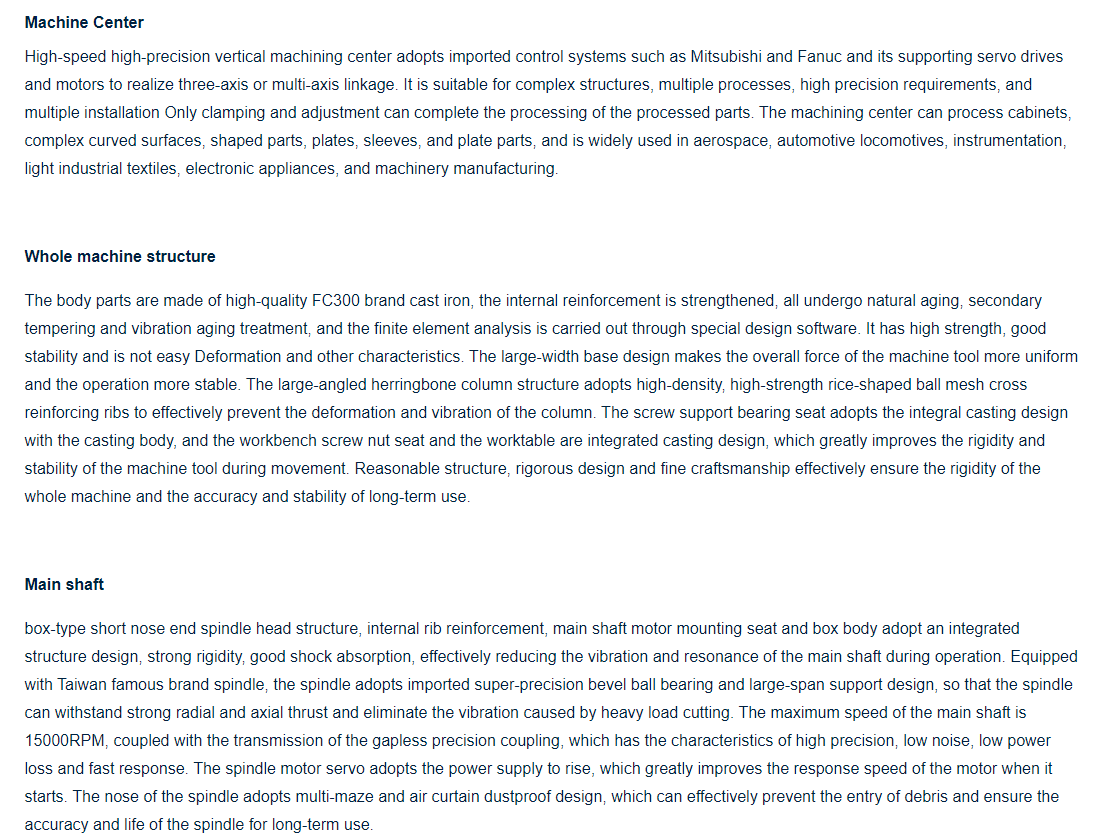

The main technical parameters

Processing size

| Model | Unit | MVP 1166 |

| Work table | ||

| Table size | mm(inch) | 1200×600(48×24) |

| T—solts size( solt number x widthx distance) | mm(inch) | 5×18×110(0.2×0.7×4.4) |

| Maximum load | Kg(lbs) | 800(1763.7) |

| Travel | ||

| X-axis travel | mm(inch) | 1100(44) |

| Y—axis travel | mm(inch) | 600(24) |

| Z—axis travel | mm(inch) | 600(25) |

| Distance from Spindle nose to table | mm(inch) | 120-720(4.8-28.8) |

| Distance from spindle center to column surface | mm(inch) | 665(26.6) |

| Spindle | ||

| Spindle taper | type | BT40 |

| Spindle Speeds | r.p.m | 10000/12000/15000 |

| Drive | type | Belt-tvpe/Directly coupled/Directlv coupled |

| Feed rate | ||

| Cutting feed rate | m/min(inch/min) | 10(393.7) |

| Rapid on (X/Y/Z) axes | m/min(inch/min) | 36/36/30 |

| (X/Y/Z) fast moving speed | m/min(inch/min) | 1417.3/1417.3/1181.1 |

| Automatic tool changing system | ||

| Tool Type | type | BT40 |

| Tool capacity | set | Arm 24T |

| Maximum tool diameter | m(inch) | 80(3.1) |

| Maximum tool length | m(inch) | 300(11.8) |

| Maximum tool weight | kg(lbs) | 7(15.4) |

| Tool to tool change | sec | 3 |

| Motor | ||

| Spindle drive motor Contimious operation / 30 min rated |

(kw/hp) | MITSUBISH 7.5/11 (10.1/14.8) |

| Servo drive motor X, Y, Z axis | (kw/hp) | 3.0/3.0/3.0 (4/4/4) |

| Machine floor space and weight | ||

| Floor space | mm(inch) | 3900×2500×3000 (129.9×98.4×118.1) |

| Weight | kg(lbs) | 7800(17196.1) |

Quality assurance

During the assembly of the fuselage, each process is quality controlled according to the 50% tolerance of the national standard, which effectively reduces the overall deviation caused by the cumulative error. After the assembly is completed, 72 hours of copying machine operation is performed to monitor various indicators such as noise, vibration, rapid movement, and tool change. Advanced equipment such as laser interferometer, ball bar, dynamic balance instrument and three-coordinate measuring instrument are used to inspect the machine tool, parts trial processing inspection, heavy cutting inspection and rigid tapping inspection, to ensure that all performances meet the factory’s high quality requirements .

Use environment

1. Operating temperature of equipment environment: 10 ℃ ~ 40 ℃.

2. Relative humidity of use environment: should be controlled within 75%.

3. The equipment should avoid the radiation and vibration of other higher heat sources to avoid machine tool failure or loss of machine tool accuracy.

4. Voltage: 3 phases, 380V, voltage fluctuation within ± 10%, power frequency: 50HZ.

If the voltage in the area of use is unstable, the machine tool should be equipped with a regulated power supply to ensure the normal operation of the machine tool.

5. Air pressure: In order to ensure the normal working performance of the equipment, if the compressed air of the air source does not meet the requirements of the air source, an air source purification device (dehumidification, degreasing, filtration) should be added before the machine tool intake air.

6. The machine tool should have reliable grounding: the grounding wire is a copper wire, the wire diameter should not be less than 10mm², and the grounding resistance is less than 4 ohms.

7. The ground wire of each CNC machine tool should be connected to a separate ground rod.

8. Grounding method: Drive a copper rod with a diameter of about Φ12mm into the underground 1.8 ~ 2.0m. The ground wire (the diameter of the wire is not less than the diameter of the power cord) must be reliably connected to the ground rod with screws.

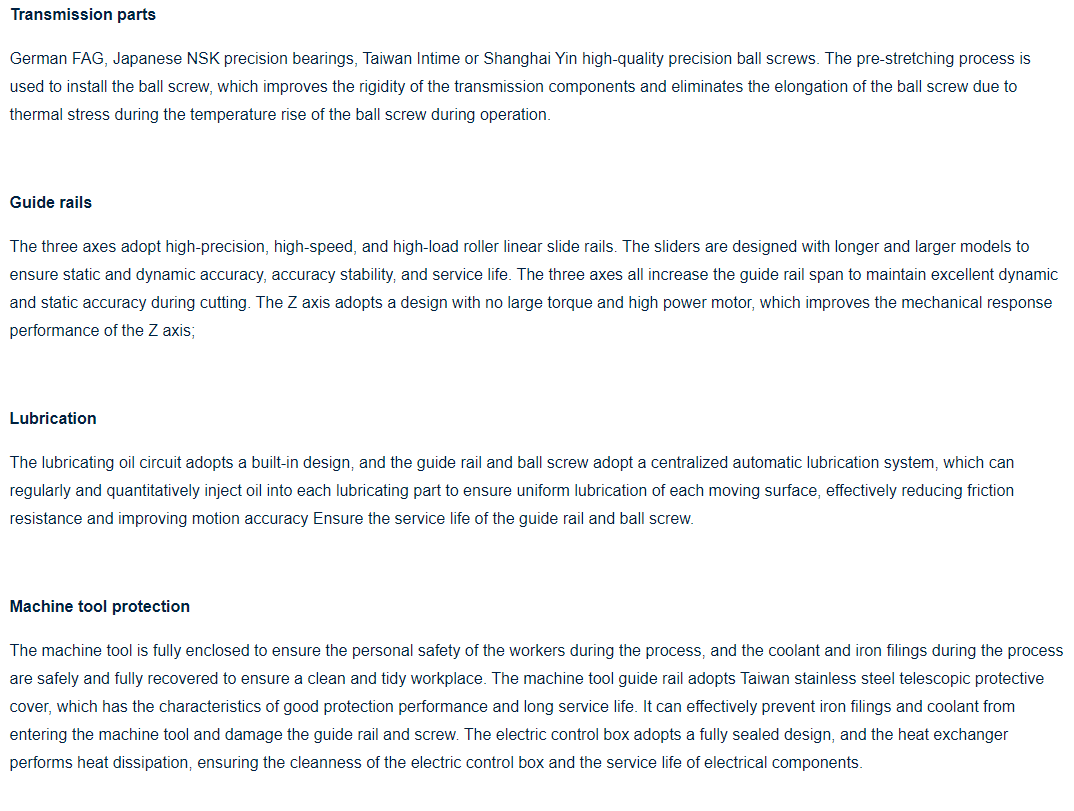

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for Low price for Vertical Machine Center Cnc - Taiwan quality Chinese price MVP1166 Machine center – BiGa , The product will supply to all over the world, such as: Puerto Rico, Grenada, Kuwait, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will provide our best service to satisfy all your needs! You should contact us right away!

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.