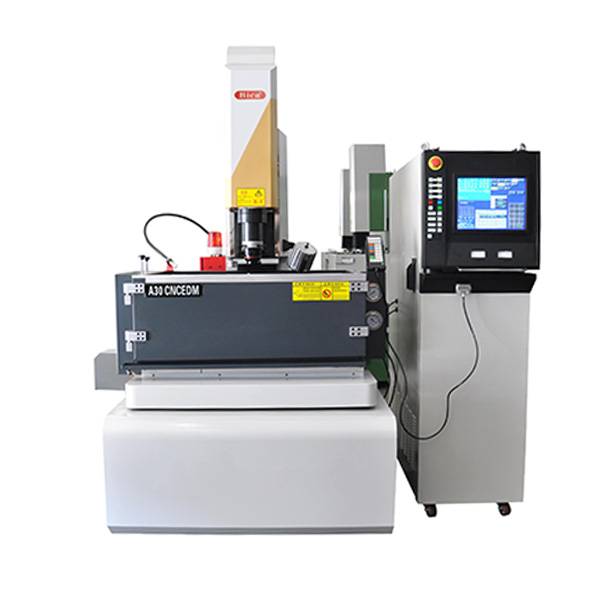

Quality Inspection for Edm Machine Wire Cutting - EDM Hole Drill Machine(XCC8-F) – BiGa

Quality Inspection for Edm Machine Wire Cutting - EDM Hole Drill Machine(XCC8-F) – BiGa Detail:

Casing: ABS polymer casing box die cast aluminum

Response Speed: 60mmin. (198.6feetmin)

Dimension: 265*182″48mm for TOP20; 290″190″105mm for BC20

Weight: 1.1KG for TOP20,2.85KG for BC20

Quantizing error: +-1count

Connection Type: 9 pin D-type

Encoder input: 5v TTL 90 quadrature phase difference

Keypad type: Membrane with PCB mounting tactile switch

Power Source: AC 110-220V, 50-60 Hz

Power: Universal power supply

Temperature: Operating 0 ~ 40 deg C,

Display: 8-digits green color LED display

General Functions

Metric/lmperial Conversion. Zero Reset. Preset Dimension

1/2 Distance Mode to aid Centre Finding. Recall Memorised Position.

Absolute and Incremental coordinate display modes.

Mechanical Zero & Workpiece Zero.

Shrink Function: Shrinkage allowance can be set to compensate for casting or moulding shrinkage.

Pitch Circle Diameter (PCD) Function: The console will output X and Y coordinates for each hole.

Calculator Functions

Maths Functions: Add, Subtract, Multiply, Divide

Trig Functions: SIN, COS, TAN, SIN-1, COS-1, TAN-1, X2, v, I (pi)

Axis position can be transferred to calculator as an operator.

Result can be transferred back to an axis

EDM Functions

EDM depth control function

Lathe Functions

Tool Compensation and Tool Number.

Diameter or Radius Reading.

Set tool compensation dimension

Mult-function Functions (for millirg, boring, lathe, gridng, ED)

1] PCD circular sub-holes (for milling, EDM)

2] Slash punch (for milling machine)

3] Tool compensation function (for milling machine)

4] Taper measurement function (for lathe)

5] Slope processing (for milling machinel

6] R arc function (for milling machine)

7] 200 tool magazine (for lathe)

8] EDM functions (for EDM, ordered separately)

9] 8S-232 communication (ordered separately)

Product detail pictures:

Related Product Guide:

Our solutions are widely recognized and trusted by consumers and will meet up with constantly developing financial and social requires for Quality Inspection for Edm Machine Wire Cutting - EDM Hole Drill Machine(XCC8-F) – BiGa , The product will supply to all over the world, such as: Croatia, Seychelles, Iraq, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!