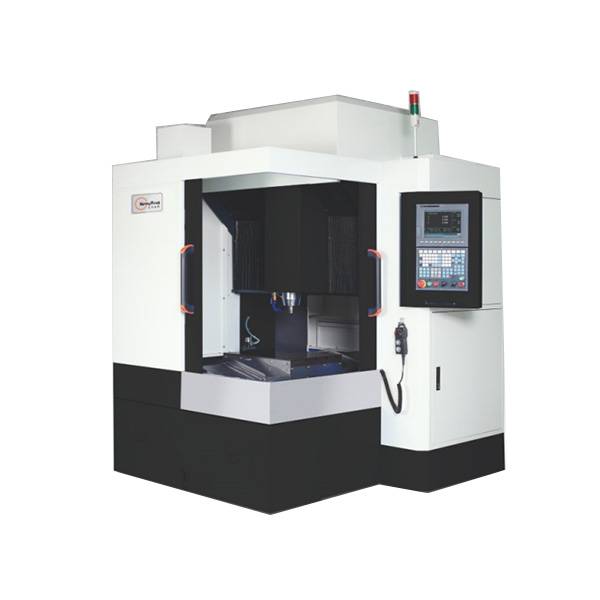

650 Engraving and milling machine

Mechanical characteristics

• The machine adopts the unique beam and bed integrated technology. Gantry type high rigidity structure. Ensure long-term high precision and service life of the machine, and strong shock resistance.

• The three-axis adopts imported high-precision linear guides and ball screws, which are wear-resistant, low friction coefficient, high positioning accuracy and flexibility, and stable movement. But it uses Japanese NSK bearings and imported couplings.

• The high-speed, high-torque, high-precision electric spindle can meet high-speed machining requirements and accuracy guarantee; it can realize high-speed ironing of small precision molds and parts, high machining accuracy, low vibration and low noise.

• The control system adopts Taiwan’s new generation, Baoyuan high-speed CNC system, which is easy to learn and use, and easy to master.

• The drive system adopts the AC drive servo system of Japan’s Yaskawa and Japan’s Sanyo, with stable operation, superior acceleration performance, low noise and high control accuracy.

| Models | unit | SH-650 |

| stroke | ||

| X axis travel | mm | 600 |

| Y axis travel | mm | 500 |

| Z axis travel | mm | 250 |

| Distance from work surface to spindle end surface | mm | 80-300 |

| Working tomb | ||

| Work size | mm | 600×500 |

| Maximum load | kg | 400 |

| Feed | ||

| Rapid feed | mm/min | 15000 |

| Cutting feed | mm/min | 1~8000 |

| Spindle | ||

| Spindle speed | r.p.m | 2000-24000 |

| Spindle dimension | ER25 | |

| The spindle cooling | Oil cooling | |

| Three axis servomotor | kw | 0.85-2.0 |

| Spindle motor | kw | 8.5 |

| other | ||

| The system configuration | The new generation,Bao yuan | |

| Resolution of NUMERICAL control system | mm | 0.001 |

| Positioning accuracy | mm | 0.005/300 |

| Repeat positioning accuracy | mm | ±0.003 |

| The knife instrument | The standard | |

| Lubrication system | Fully automatic lubrication system | |

| Machine weight | kg | 3100 |

| Mechanical dimensions | mm | 1730 ×1930 x2400 |