Taiwan quality Chinese price SVP Series Vertical Machining Center

SVP Series

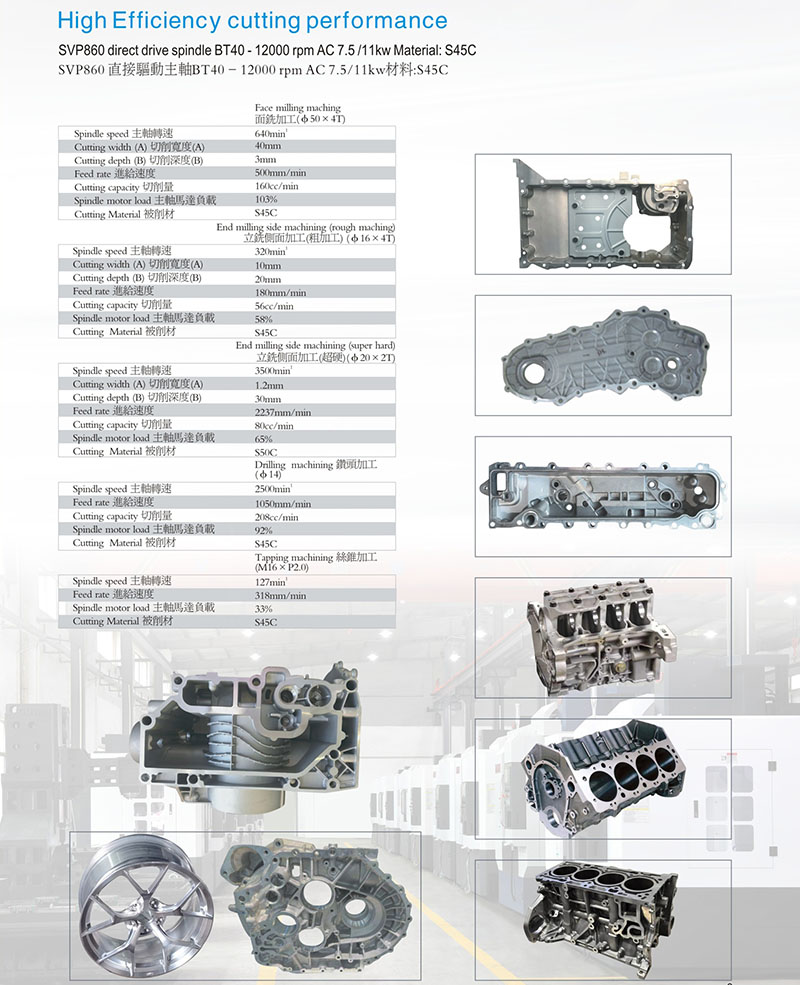

MVP Series is satisfy customers' needs of high- speed, high- accuracy and high- rigidity cutting equipment.

Feature

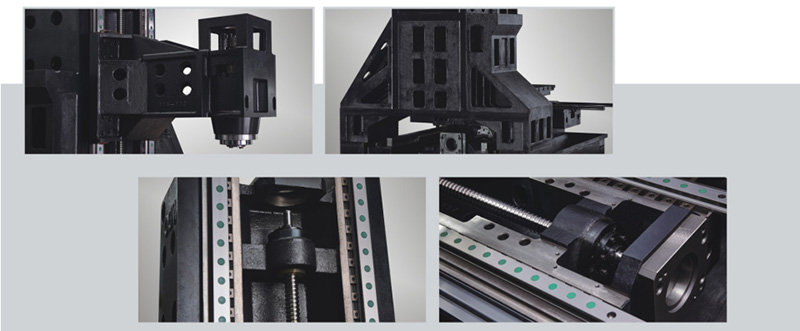

1.Heavy, wide- body structure and high standards machine accessories ensures high-rigidity and high- accuracy of machine.

2.45mm ultra - heavy load, high accuracy, low friction coefficient roller linear guide ways, the overall motor base together with diaphram coupling can provide the high keen dynamic performance.

3.Increasing the bottom supporting point of the machine and enlarging the horizontal screws can better absorb the processing load and the appropriately transfer a part ofload to the ground.

4.The machine body is made by best Meehanite cast iron, and all major contact surface are all scrapped by excellent skill, which not only improve the overall performance ofthe machine, but also prolong the working life of the machine.

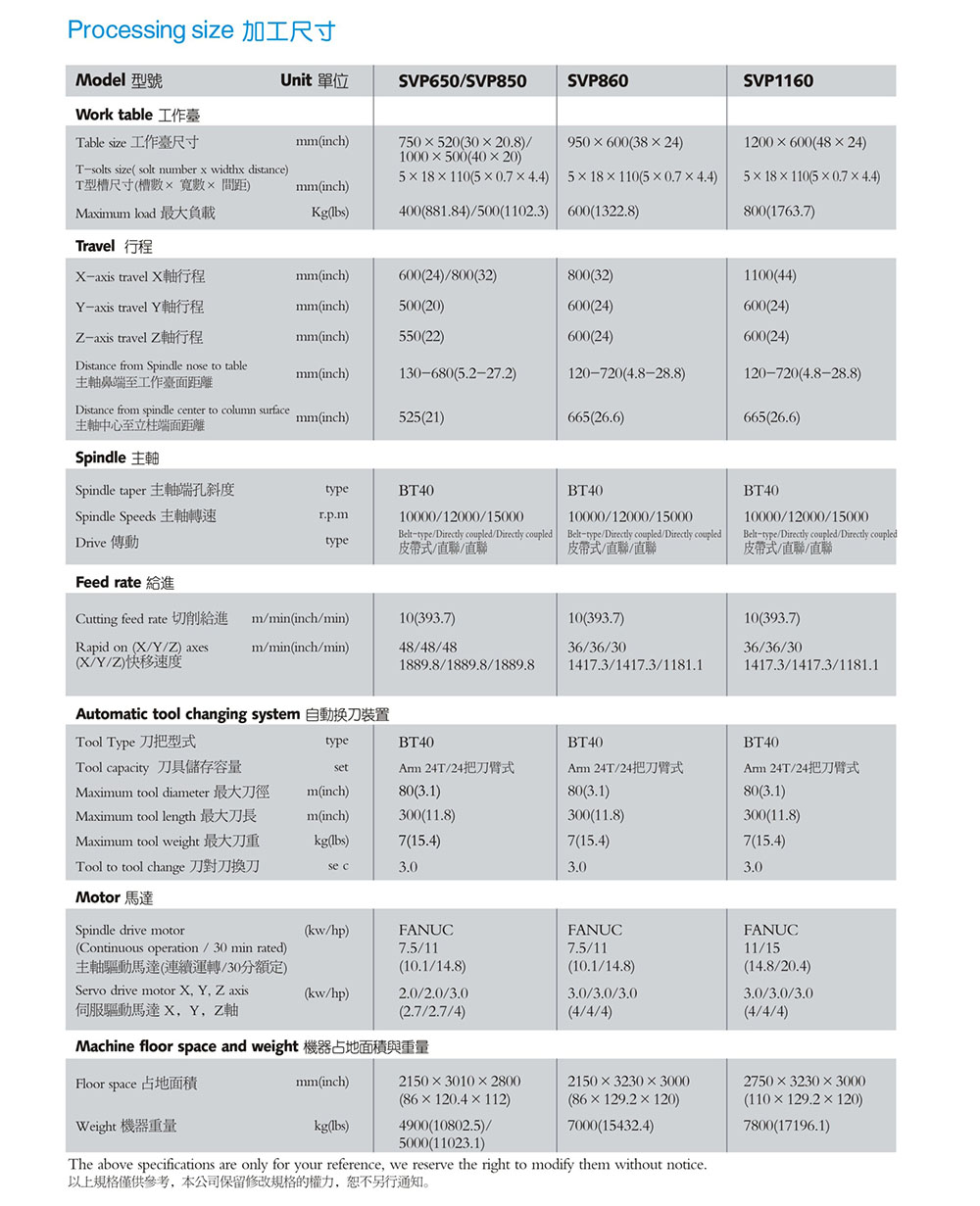

Travel, table size, load

| Table size | Unit | SVP650 | SVP850 | SVP860 | SVP1160 |

| Long (X) | mm | 750 | 1000 | 950 | 1200 |

| Width(Y) | mm | 520 | 500 | 600 | 600 |

| Load | kg | 400 | 500 | 600 | 800 |

| Travel | Unit | ||||

| x-axis travel (left and right) |

mm | 600 | 800 | 800 | 1100 |

| Y-axis travel(front and back) |

mm | 500 | 500 | 600 | 600 |

| z- axis travel (up and down) |

mm | 550 | 550 | 600 | 600 |

All parts are precise manufactured, careful ad justment and strict assembly.

Standard accessories

Rigid tapping

10000rpm/11kwspindle belt type 10000rpm/11kw

spindle tool release equipment

Spindle oil chiller (spindle oil temperature cooler)

Spindle purge air curtain

Coolant through spindle

workpiece cutting coolant system

workpiece blowing coolant system

Coolant liquid tank

strong flushing system

Cleaning Gun、Air gun

Central automatic lubrication system

Three axis bearing lubrication system

double spiralchip conveyor

Arm type tool magazine ATC24P

Tool changer chip-proof aling device

Transformer

Automatic power-off function

Heat exchanger for electric cabint

Hand-Held Unit一handing pulse

Rs232 transmission interface Rs232

Three-color warning light/Working light

all-closed guard shield

three axis guide railguard shield

three axis line guide rai

Oily Water Separator

basic pad and tool box

|

optional accessories |

optional accessories | T echnical package |

| spindle center water output (with filter)the forth axisHydraulic station (Taiwan) without electronic valvedirect coupled spindle12000rpm/7.5kw

belt-type spindle 8000rpm/ 18.5kw Chain-plate dust collector oil collector、air conditioner for electric box Z axis heighten 300mm |

tool setting gaugecutting fluid level detecting deviceautomatic doorOperator safety barriers of automatic doorDoor Interlock Device

electric oil - water separator Hydraulic station (China) without electronic valve |

10000rpm High rigidity(belt -type spindle)spindle cylinder24P arm type equency- conversionTool change time

T toT: 2.5 sec CtoC: 4.5 sec enlarge I0 storage, electrical equipment upgrade,point to point panel Z axis heighten 200mm |

Spindle vibration testing

Using Germany W ENZEL 3D CMM machine to make sure spindle quality

Renishaw laser interferometer

Follow German VDI3441 standard testing to ensure the positioning and repeatability accuracy.

Renishaw ballbar

Optimized circular interpolation in x,y,z planes by tuning each servo drive.

3D coordinate measurement

The main parts of the machine testing before assembly and the accuracy testing of the experiment processing parts.