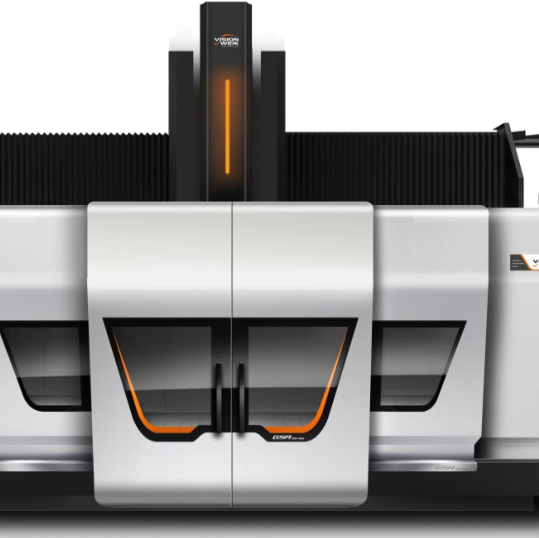

5-axis Gentry type machining center Vision Wide

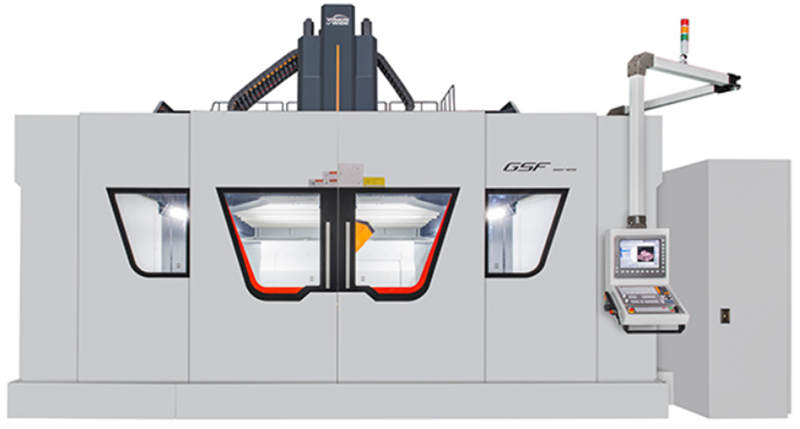

GSF Series 5-axis Gantry Type Machining Center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively and extend tool life and offer the best choice for composite angle machining. GSF Series had an excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

Continuous 2-axis head

5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

Built-in Spindle Direct-Driven on B&C axis, 15,000~24,000rpm spindle speed.

Backlashless driving on B/C axis, Rotation Positioning accuracy ±5″.

Low table height, closer operating zone, and wider door width are convenient designs for users.

Chain type chip conveyor (standard) is able to remove iron chips efficiently.

Industries Applications:

Aerospace-Aluminum Frame

Automotive- Stamping Die

Mechanical Component

Specification:

| Model | Unit | GSF-1627 | GSF-2227 | GSF-3027 | GSF-4027 | GSF-5027 | GSF-6027 |

| X axis travel | mm | 1,600 | 2,200 | 3,000 | 4,000 | 5,000 | 6,000 |

| Y axis travel | mm | 2,700 | |||||

| Z axis travel | mm | 1,000/1,200 | |||||

| Table dimension | mm | 1,600 x 2,700 | 2,200 x 2,700 | 3,000 x 2,700 | 4,000 x 2,700 | 5,000 x 2,700 | 6,000 x 2,700 |

| Max. table load | kg/m2 | 3,000 | |||||

| Spindle motor power(S1/S6) | kW | 50/65 | |||||

| Spindle speed | rpm | 15,000 | |||||

| Cutting federate | mm/min | 1-20,000 | |||||

| Rapid traverse (X/Y/Z) | m/min | XY:32 / Z:20 | |||||

| ATC capacity | pcs | 20/32/40/60 | |||||

| Model | Unit | GSF-2232 | GSF-3032 | GSF-4032 | GSF-5032 | GSF-6032 |

| X axis travel | mm | 2,200 | 3,000 | 4,000 | 5,000 | 6,000 |

| Y axis travel | mm | 3,200 | ||||

| Z axis travel | mm | 1,000/1,200 | ||||

| Table dimension | mm | 2,200 x 3,200 | 3,000 x 3,200 | 4,000 x 3,200 | 5,000 x 3,200 | 6,000 x 3,200 |

| Max. table load | kg/m2 | 3,000 | ||||

| Spindle motor power(S1/S6) | kW | 50/65 | ||||

| Spindle speed | rpm | 15,000 | ||||

| Cutting federate | mm/min | 1-20,000 | ||||

| Rapid traverse (X/Y/Z) | m/min | XY:32 / Z:20 | ||||

| ATC capacity | pcs | 20/32/40/60 | ||||

Standard accessories:

| HEIDENHAIN TNC640 controller |

| HEIDENHAIN DCM (Dynamic Collision Monitoring) |

| 15,000 rpm HSK-A100 spindle |

| 2-axis head centeral monitoring protection system: |

| Spindle bearing vibration monitoring |

| Spindle and motor temperature monitoring |

| B/C-axis motor temperature monitoring |

| Spindle cutting load software protection |

| Spindle and structure temperature thermal compensation system |

| Spindle cooling system |

| Spindle ring cutting coolant device(for no head attachment) |

| Air blast through spindle |

| 2-axis Head rotary compensastion system |

| Z-axis travel 1,000 mm |

| Ball screw cooling system |

| X/Z axis are driven by dual ballscrew and Y axis is driven by single ballscrew |

| X/Y/Z axis high rigidity roller type linear guideway |

| X axis ball screw support device (axis 4m above) |

| X axis dual linear scale, Y/Z-axis linear scale |

| XYZ-axis travel hard limits protection |

| Centerlized auto lubrication system |

| Independent lubrication oil collector |

| Wash gun and pneumatic interface |

| Vertical type tool magazine 20T with arm type ATC |

| Swiveling arm type operation panel |

| Movable manual pulse generator |

| Air conditioner for electrical cabinet |

| Working lamp |

| Operation cycle finish and alarm light |

| RJ45 interface |

| Enclosed sheet metal guard without roof |

| Screw type chip conveyor on table sides |

| Caterpillar type chip conveyor / Water tank |

| Cutting fluid cooling system |

| Footswitch for tool clamping |

| Remote monitoring software-standard |

| Auto power off function |

| Z-axis retract function at power failure |

| Foundation pads and bolts kits |

| Adjustment tool and tool kits |

| Technical manuals (operation, maintenance manual and circuit diagram)) |

Optional accessories:

| 24,000 rpm HSK-A63 spindle |

| 12,000 rpm HSK-A100 spindle |

| Z-axis travel 1,200 mm |

| Vertical type tool magazine 32/40/60T with arm type ATC |

| Coolant through spindle system:20 bar / 60 bar |

| Oil mist cooling device |

| Oil skimmer |

| Helical blade screw conveyor on table sides |

| Dual belt type chip conveyor / Water tank |

| without chip auger / without chip conveyor / without tank |

| Foot pad above chip groove |

| Chip cart |

| Enclosed sheet metal guard with roof |

| Sub working table |

| XYZ-axis independent manual pulse generator |

| Remote monitoring software-professional |

| Auto tool length measurement |

| Auto workpiece coordinate measurement |

| Automatic correction software of rotary axis error |

| Spindle vibration protection device |

| Transformer |

| Oil mist recycle device |

| Intelligent feed machining function |