Drill Hole Machine - China Manufacturers, Suppliers, Factory

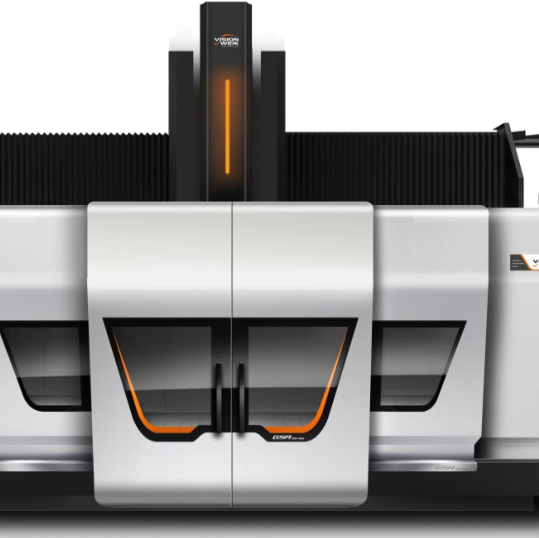

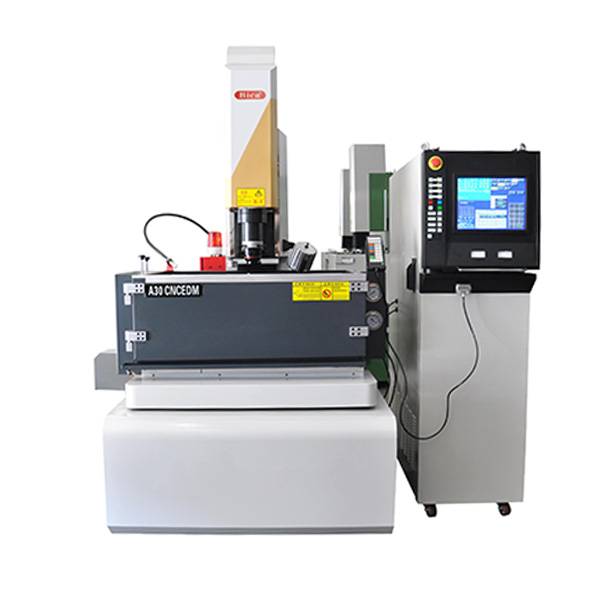

We retain bettering and perfecting our goods and service. At the same time, we perform actively to do research and enhancement for Drill Hole Machine, Horizontal Image Measuring Instrument , Plastic Dro , Wirecut Edm Erosion Machine ,High Precision Cnc Milling Machine Center . Now we have extensive goods source as well as price tag is our advantage. Welcome to inquire about our products and solutions. The product will supply to all over the world, such as Europe, America, Australia,Cyprus, Finland,Argentina, Armenia.Our products and solutions are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, be sure to contact us today. We will sincerely create and share success with all clients.

Related Products